PCD and CBN inserts are rapidly becoming the choice of many machine shops over Carbide cutting tools. This is mainly due to the benefits that come with using these inserts such as high machining accuracy, high surface finishing quality, and increased tool life.

Among the countries that have embraced the use of CBN cutting turning inserts in particular is Korea. These inserts have become very popular among Korean machining companies due to their high performance and precision. Korean companies have found that CBN outperforms ceramics by more than 30 times when machining cast iron, making it an ideal choice for industrial processes.

CBN (Cubic Boron Nitride) is a synthetic material that has been designed to have a high level of hardness and wear resistance. This makes it ideal for machining applications, especially in the automobile and aerospace industries. CBN is chemically inert and does not react with metals, making it ideal for use in high-temperature environments.

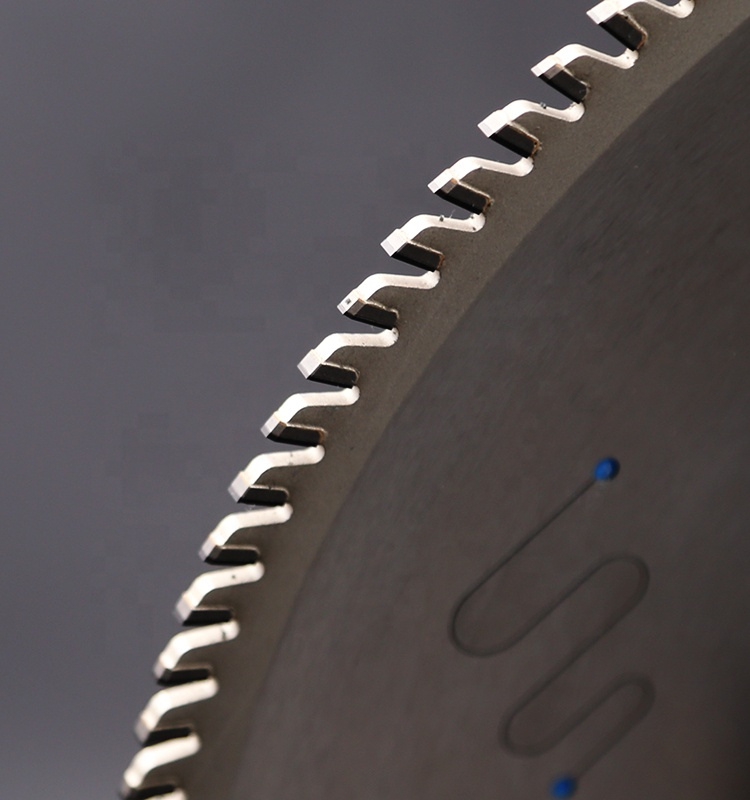

Turning inserts are a key component of any machining process. They are used to cut materials such as metals, plastics, and ceramics into various shapes and sizes. CBN turning inserts offer a range of benefits that make them the first choice of many machine shop operators. These benefits include longevity, accuracy, and high surface finishing quality.

Korean machining companies, like many others around the world, have realized that CBN turning inserts can help them make substantial savings while increasing productivity. The use of CBN inserts in turning has also opened up new machining possibilities as it allows more complex shapes to be achieved.

Another aspect that sets CBN inserts apart from other inserts is the option for coatings. Coated PCD and PCBN inserts last even longer and can handle higher cutting speeds and coolant pressure. A typical coating layer will be around 1-4 microns but can go up to 10 microns or more. This makes these inserts ideal for more intense and heavy-duty machining applications.

In conclusion, diamond cutting tools especially PCD and CBN inserts are rapidly becoming the tool of choice for machining companies due to their high accuracy, longevity, and surface finishing quality. CBN turning inserts, in particular, have helped Korean machining companies to make significant savings while increasing productivity. The addition of coatings further enhances the benefits of CBN inserts, making them suitable for intense and heavy-duty machining applications.