Cutting and drilling tasks require precision, speed and efficiency to produce high-quality outputs. This is where carbide inserts come into play. Carbide inserts, also known as tungsten carbide inserts, are specialized cutting tools commonly used in the manufacturing industry for drilling, cutting and milling purposes. Carbide inserts are engineered to handle extreme pressure, heat and wear that is typical in drilling and cutting applications.

Carbide inserts are made from high-quality materials that ensure durability and longevity. They are made of a composite material that includes tungsten carbide and a binding material, such as cobalt, that holds the carbide in place. This ensures that the carbide inserts remain sharp and effective for longer periods of time, resulting in less downtime and improved productivity.

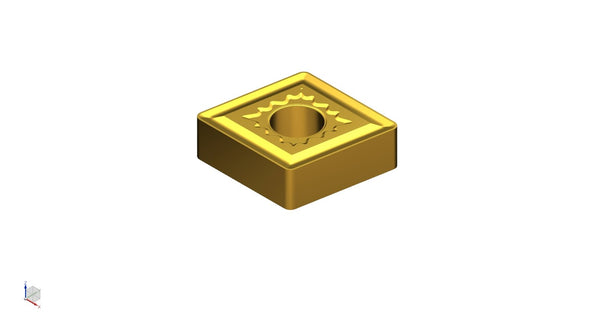

There are several different types of carbide inserts that can be used depending on the application. These include TNMG, CNMG, DNMG and WNMG. Each type of carbide insert offers specific benefits depending on the application.

TNMG carbide inserts, for example, are designed for turning applications and offer a high level of accuracy and surface finish. CNMG carbide inserts are ideal for roughing and semi-finishing, while DNMG carbide inserts are most commonly used for finishing and profiling operations. Finally, WNMG carbide inserts are designed for heavy-duty cutting and roughing applications and are ideal for milling operations.

Carbide inserts are the preferred choice for many manufacturers due to their high precision, speed and efficiency. They offer numerous benefits over traditional cutting tools, including:

- Longer tool life: Carbide inserts can last up to ten times longer than traditional cutting tools, resulting in less downtime and improved productivity.

- Faster speeds: Carbide inserts can be used at higher speeds than traditional cutting tools, resulting in faster production times and increased efficiency.

- Enhanced surface finish: Carbide inserts offer a high level of accuracy and surface finish, resulting in higher quality outputs.

In conclusion, carbide inserts are the ultimate choice for cutting and drilling applications in the manufacturing industry. They offer numerous benefits over traditional cutting tools, including longer tool life, faster speeds, and enhanced surface finish. With numerous types of carbide inserts available, including TNMG, CNMG, DNMG and WNMG, there is a carbide insert available for every application. So, whether you are engaged in turning, roughing, finishing or heavy-duty cutting, carbide inserts can help you achieve faster, smoother, and more efficient operations.